Lean Construction

An Introduction to Lean Construction

Construction labor efficiency/productivity has decreased while all other non-farming labor efficiency has doubled or more since the 1960s. Currently, 70% of projects are over budget and delivered late. The industry still sees about 800 deaths and thousands of injuries per year.

The silos created around architects, engineers, general contractors, trade contractors and specialty providers have introduced significant waste into the delivery system. A lack of trust has created systems of checks, double-checks and over specification to cover legal ramifications both real and perceived. These are the problems that Lean construction seeks to solve. Evidence from three LCI-funded research sources show that projects that implement Lean building tools and techniques have much better outcomes across a variety of benchmarks.

What is Lean Construction?

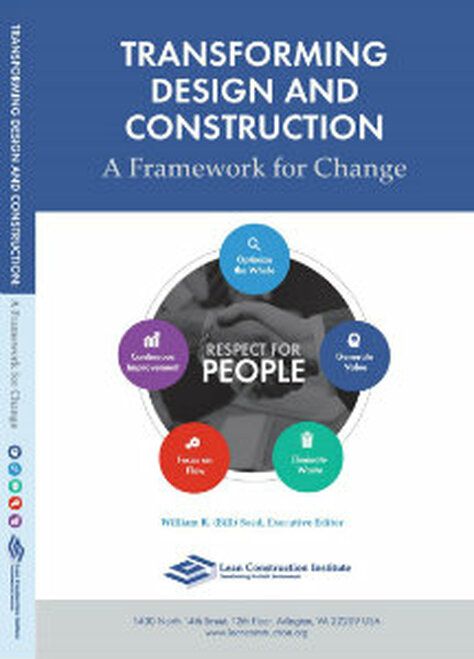

Lean construction is a project delivery process that uses Lean methods of maximizing stakeholder value while reducing waste by emphasizing collaboration between teams on a project. The goal of Lean construction is to increase productivity, profits, and innovation in the industry.

Lean Construction In Practice

The vast majority of construction projects utilize design-bid-build or design-build contracts, which separate the various parties of a project into smaller, separate projects agreeing to separate contracts.

This leads to tunnel vision among the individual parties in which each group is only interested in the success of their part of the process. If an issue arises, fingers point in every direction and nobody actually attempts to solve the problem at hand. These project delivery methods suffocate innovation because nobody has financial incentive to improve outcomes.

Utilizing Integration

Lean construction practices use an Integrated Project Delivery (IPD) system to align the owner, design team, and construction team (as well as any additional contractors) onto a single contract. Financial targets are agreed to when the contract is signed and parties split profits (and savings), giving everyone skin in the game when it comes to improving outcomes.

By aligning the various parties onto one single agreement, every party becomes contractually involved in each step of the design and construction process. The building team will be in the room during the design stage and the designers will remain involved throughout the project’s construction.

Utilizing Innovation

Trust and collaboration are necessary ingredients to create an environment where innovation can thrive, and a team that is working together towards a common goal is more likely to seek new ways to solve problems. In the end, that generates more value for the stakeholders.

The History of Lean Construction

Henry Ford is often thought of as the grandfather of the Lean methodology with his creation of the assembly line for the Model T in the early 1900s. But the use of Lean in design and construction actually begins with the erecting of the Empire State Building, even if they didn’t know it at the time.

The 1930s - 1990s

Design on the Empire State Building began in late 1929. Construction started in early 1930, and the construction process was completed just a year later. Today, it seems remarkable that the tallest structure of the early 20th century was built not only ahead of schedule, but under-budget too. At their most productive, Empire State Building workers were building a floor a day.

The term “Lean Construction” wasn’t officially coined until 1993, just four years before the Lean Construction Institute was founded. Since then, construction projects around the world have benefited from Lean construction practices.

Today

In 2011, the T-30 Hotel in China was built using Lean production tools and methods. The 30-story building was put together in just 15 days and included a number of innovative features including five times the standard earthquake resistance for the area. Impressively, zero people suffered work-related injuries during the building’s construction.

This is the standard that Lean construction production management seeks to set. Through a mindset of making continuous improvements to practices and methods, Lean construction aims to maximize value for stakeholders while minimizing waste and improving efficiencies across the board.

Lean Construction in the Long Haul

The construction industry is wasting time, money and resources at an alarming rate. Lean streamlines logistics, creates a culture of collaboration, eliminates waste and overages and ultimately leads to more value for stakeholders.

Collaboration

When construction projects adopt the collaboration-based systems of Lean building, processes are immediately improved within the present project. However improvement is seen even more over time with subsequent projects as each team member begins to master Lean tools and techniques.

Collective Knowledge

By harvesting the collective knowledge of the world’s designers and builders, the Lean Construction Institute believes that we can solve any problem in our industry. By adopting a mindset of continuous improvement, we can even prepare for future challenges.

Learning Lean Construction Principles

The Lean Construction Institute is committed to transforming the design and construction industry by providing Lean educational resources, conducting research, and facilitating local and national Lean events. It is only through the power of the LCI Corporate Members that LCI is able to offer the supplementary resources below.

Lean Assessments

How strong is your Lean knowledge? Take a Lean assessment to determine your current state so you have a baseline for improvement. Lean assessments are available for individuals, teams, and organizations alike. Whether you’re new to Lean or are an experienced Lean practitioner, Lean assessments are a great way to get started at LCI!

TAKE ASSESSMENTMore Lean Topics

From 5s to IPD, explore popular Lean design and construction topics below.